We give your drill holes the finishing touch!

In the 100 years of our company history, it was and is our aim to keep developing and expanding our range of services.

Since mid-2014 we have specifically expanded our range of services with the area of internal round honing.

We are the first company in Germany to be able to carry out internal round honing work from Ø 4 to Ø 51 and up to a depth of 1,500 mm on one side and 3,000 mm on two sides.

Fundamentals

What is cross sanding?

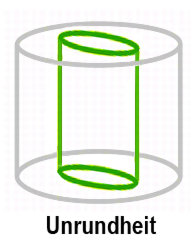

Cross sanding is honing! With a multi-cutting sanding strip made of bonded grain, material is removed with constant surface contact between the sanding strip and the workpiece.

That means that during processing, the sanding strip in the cross sanding tool is spread open using a wedge or cone. The abrasive grains, which are thereby pressed against the wall of the bore, remove material from the bore up to a preselected amount.

This work process takes place with constant rotating and lifting movements of the cross sanding tool as well as permanent cooling and lubrication with a cooling lubricant.

How is the cross cut created?

The typically crossed sanding paths are created by an oscillating stroke movement and a superimposed rotary movement of the tool or workpiece.

The resulting cross sanding angle can become steeper or flatter by increasing or decreasing the lifting speed and/or the spindle speed.

Where is cross sanding used?

Everywhere where:

-

-

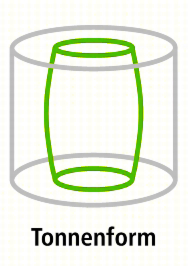

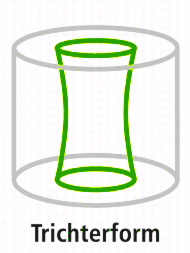

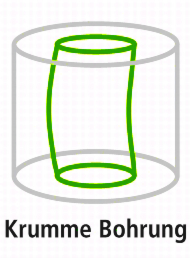

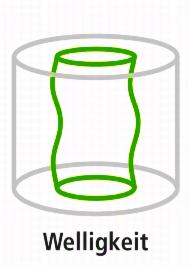

- a dimensionally and geometrically accurate drill hole is required

- a high surface quality must be produced

- high efficiency and flexibility is required

-

With diameter ranges from: 1.5 -1,500 mm

With workpiece lengths up to: 20,000 mm (standard)

What advantages does cross sanding offer?

-

-

-

- Easy mounting of the workpieces

- Universally applicable, from portable cross sanders to cross sanders with automatic loading and unloading

- Machining of workpieces with an unfavourable diameter-length ratio

- Machining of almost all materials, e.g. plastics, non-ferrous metals, all steels, carbide and ceramics

- High and fast cutting performance

- Achievement of shape and diameter tolerances down to the last µ, even at high volumes

-

-

Karnebogen GmbH

Hagener Straße 3

58566 Kierspe-Vollme

Telephone: +49 2359 / 7344

Fax: +49 2359 / 4566

E-Mail: post@karbo.de

Business hours

Monday – Thursday

07:00 – 12:00 and 13:00 – 16:00

Friday

07:00 – 12:30